What is a FFU Testing

& Commissioning?

To ensure our products as a cleanroom equipment supplier in Malaysia works in a real-time cleanroom setting, we carry out functional testing on each of our FFU (EC or AC) after installation at the site. This ensures it to run as per customer’s requirement as well as meeting the design specification needs for a cleanroom.

Why choose this service?

regulatory compliance

Adheres to ISO14644-1: 2015 standards, covering a range of parameters including room temperature, % relative humidity, viable and non-viable particulate, pressure differential, HEPA filter integrity, and more.

Enhanced services

Ensures adherence to regulatory requirements, industry standards and guidelines such as ISO or Good Manufacturing Practice (GMP). Guarantees the quality, reliability, and consistency of the cleanroom, essential for product integrity and safety.

operational efficiency

Contributes to improved operational efficiency, optimized workflows and enhanced productivity, crucial for maintaining competitive advantage in industries sector such as semiconductor, pharmaceuticals, hospital, research lab, biotechnology and medical devices.

FFU Control System T&C Process

What is a FFU Software

VFMCS - FFU Control System?

Features of The Software

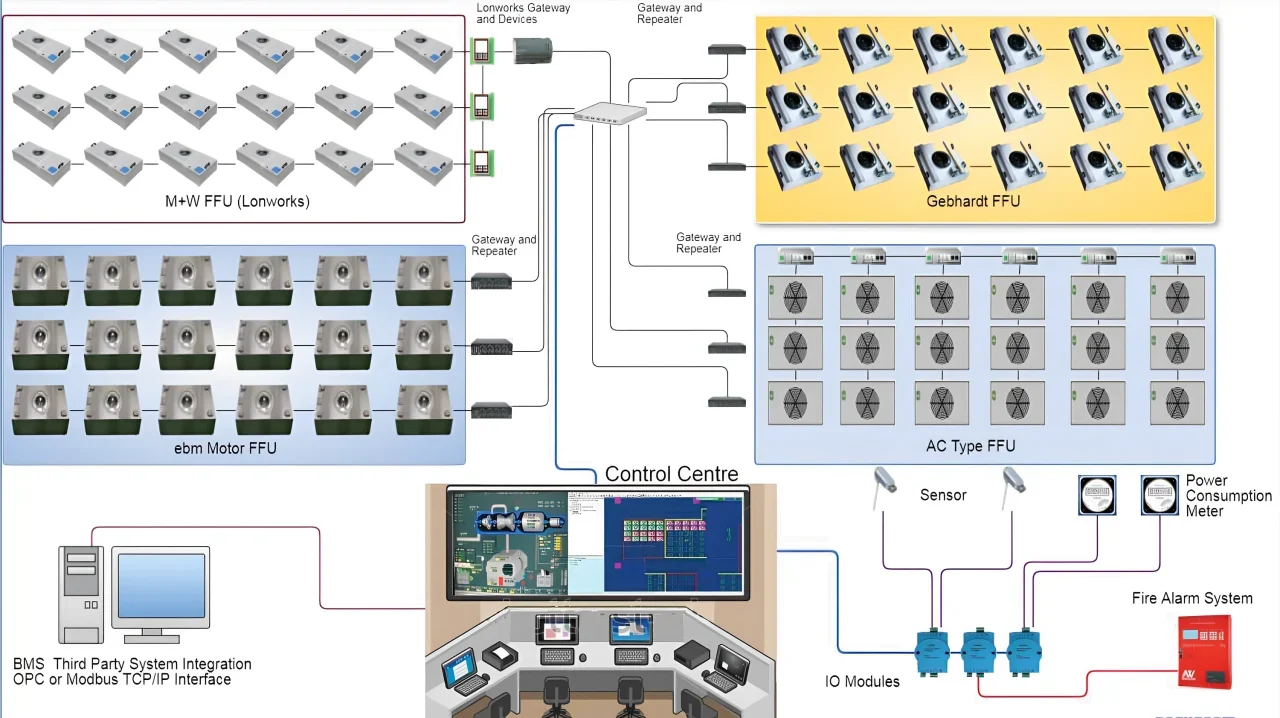

Multi-Brand Compatibility

Control and monitor multiple brands of Fan Filter Units (FFUs) including ebm Motor FFU, Gebhardt Gbus and Lonworks FFU, M+W FFU, Envirco FFU, AirCare FFU, Ziehl-Abegg FFU, and Korea Syswork Motor FFU.

Sensor Integration

Connect various sensors such as Velocity, Pressure Differential, and Fire Alarm Sensors. Supports IO modules with Modbus TCP, Advantech, and Moxa.

Communication Channels

Configure up to 127 communication channels or ports with support for USB to RS485 converters, PCI to serial port cards, Ethernet to RS485 server gateways, and Lonworks gateways.

System Capacity

No limitation on the number of FFUs in a system. Supports multiple FFU types co-existing in a single system.

| Feature | Details |

|---|---|

| Control and monitoring multiple brands of Fan Filter Unit | Supported Brands: • ebm Motor, any vendors FFU use ebm motor; • Gebhardt FFU, Gbus and Lonworks protocol; • M+W FFU, lonworks; • Envirco FFU, Modbus; • AirCare FFU, Modbus; • Ziehl-Abegg FFU, Modbus; • Korea Syswork Motor FFU; • AC FFU control by inverter; |

| Built-in sensor integration | Able to connect Velocity Sensor, Pressure differential Sensor, Fire Alarm Sensor as well as any IO signal: • Any brand of IO module supported Modbus TCP, Advantech, Moxa • Dwyer velocity sensor |

| Configure up to 127 communication channels or ports | Supported direct USB to RS485 converter, multiple PCI to serial ports card, Ethernet to RS485 server Gateway, Lonworks gateway |

| Multiple type of FFU coexist in single system, no limitation of number of FFU in a system | Example: for an existing M+W FFU system, ebm Motor FFU can be added or to replace faulty M+W FFU |

| Beside of support Vector drawing layout plan, it also support common picture file format like JPG, PNG | FFU layout plan Autocad dwg file exports to vector drawing WMF or EMF, and import to system. |

| Up to 5 level of hierarchy tree structure, option to create zone level | Tree Structure • Overview home page • Cleanroom C • Zone (Optional) • Group XX • FFU |

| Fast response time | Scan FFU status and rpm concurrently: all of configured communication channels or ports scan their FFU status and speed concurrently; 25,000 FFU, connected to 92 communication channels, response to rpm change within 10 seconds. |

| Display real time speed and status on individual FFU icon | |

| Display power estimated consumption and FFU online rate for individual channels or ports | |

Control FFU

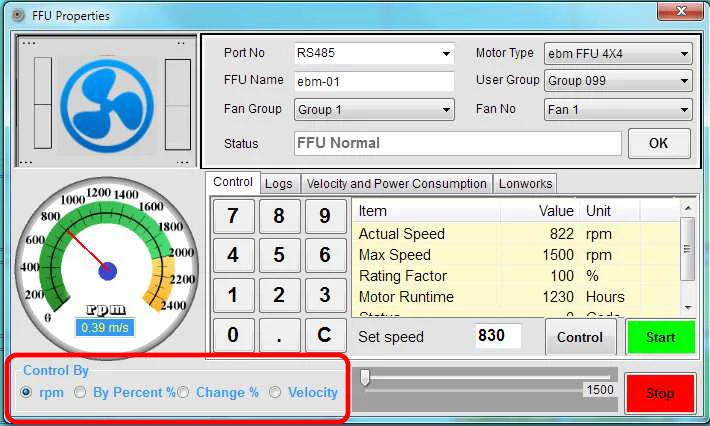

Control individual FFU

• By rpm;

• By Velocity;

• By Change %, increase or decrease %;

• By Percentage, % of Max speed;

Velocity and Power Consumption cures

By measuring serial of velocity and power consumption data, and use statists tools to generate velocity and power consumption formula; formula parameters can be set in system options setup page;

Click on any point of cure, and click

<Set New rpm to :xxxx> to set speed to meet velocity.

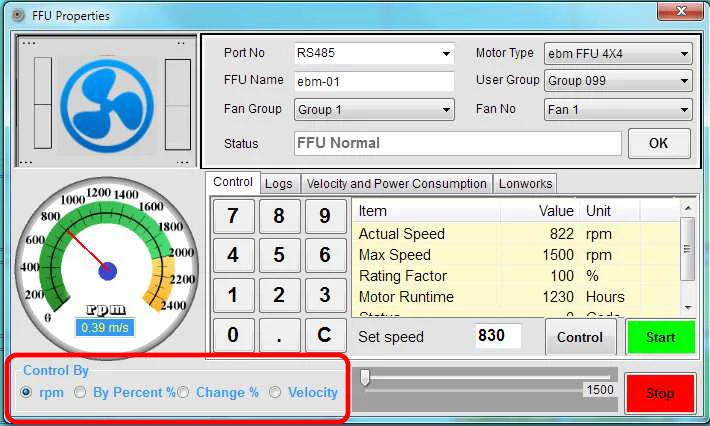

Control individual FFU

• By rpm;

• By Velocity;

• By Change %, increase or decrease %;

• By Percentage, % of Max speed;

Velocity and Power Consumption cures

By measuring serial of velocity and power consumption data, and use statists tools to generate velocity and power consumption formula; formula parameters can be set in system options setup page;

Click on any point of cure, and click

<Set New rpm to :xxxx> to set speed to meet velocity.

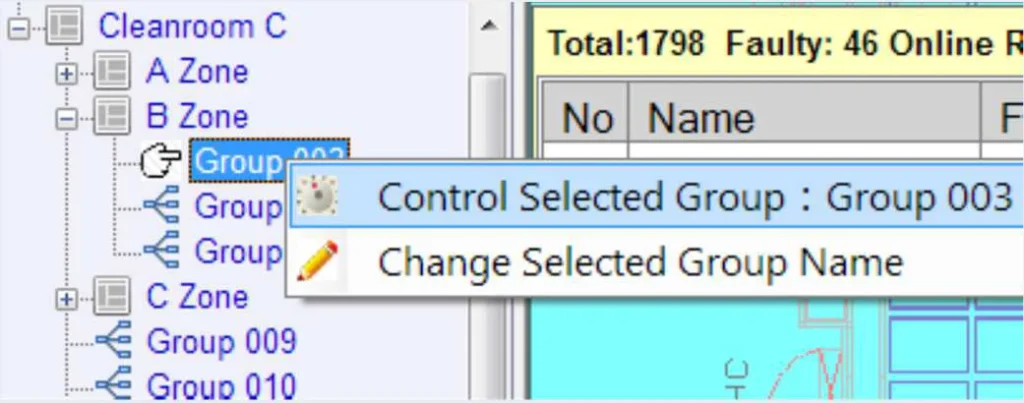

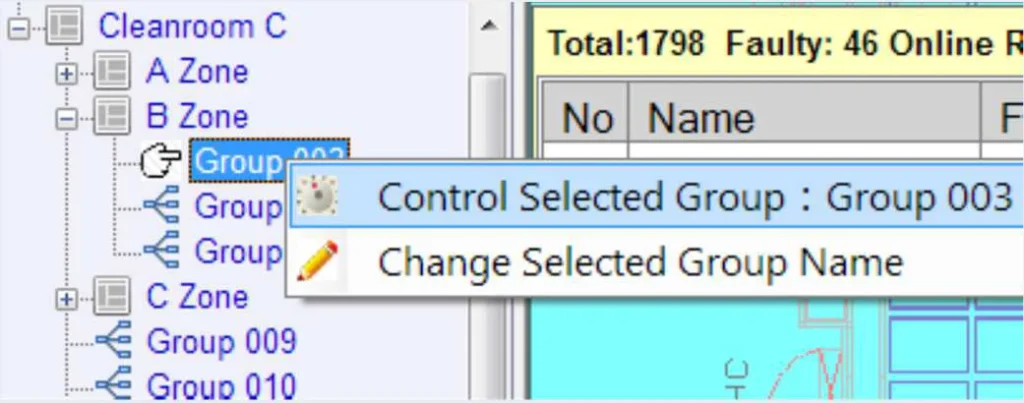

Group Control

Control individual Group

Select a Group from left hand side tree view panel, right click shown popup menu, and select <Control Selected Group: Group XXX>

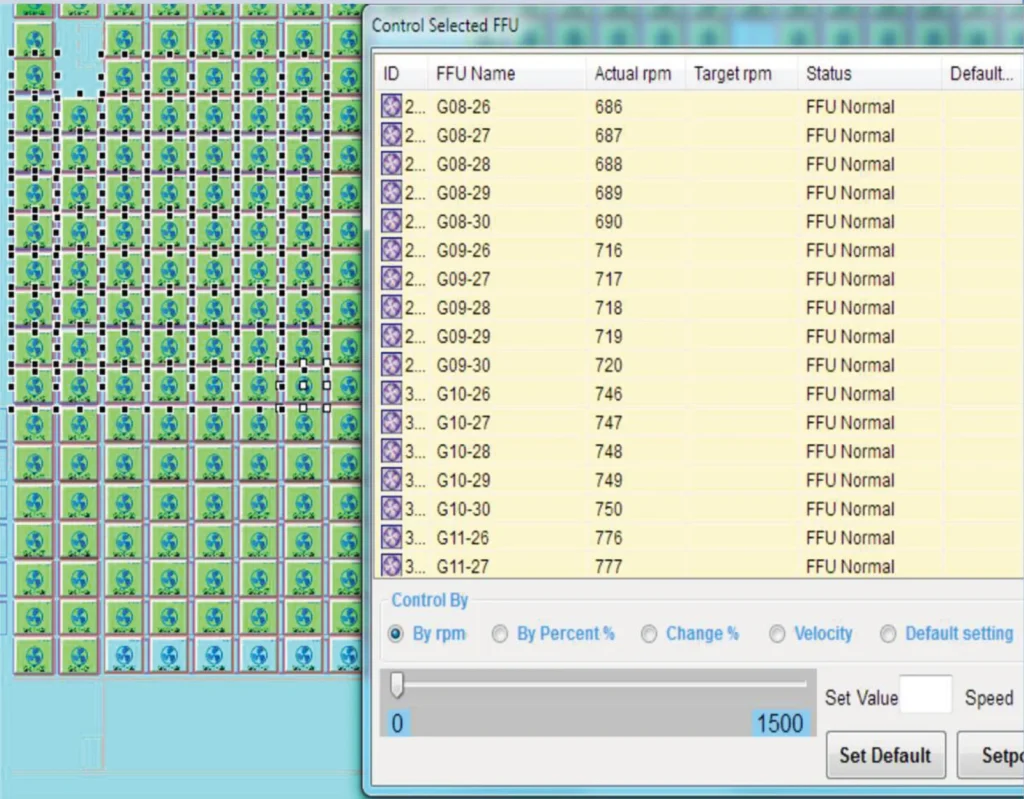

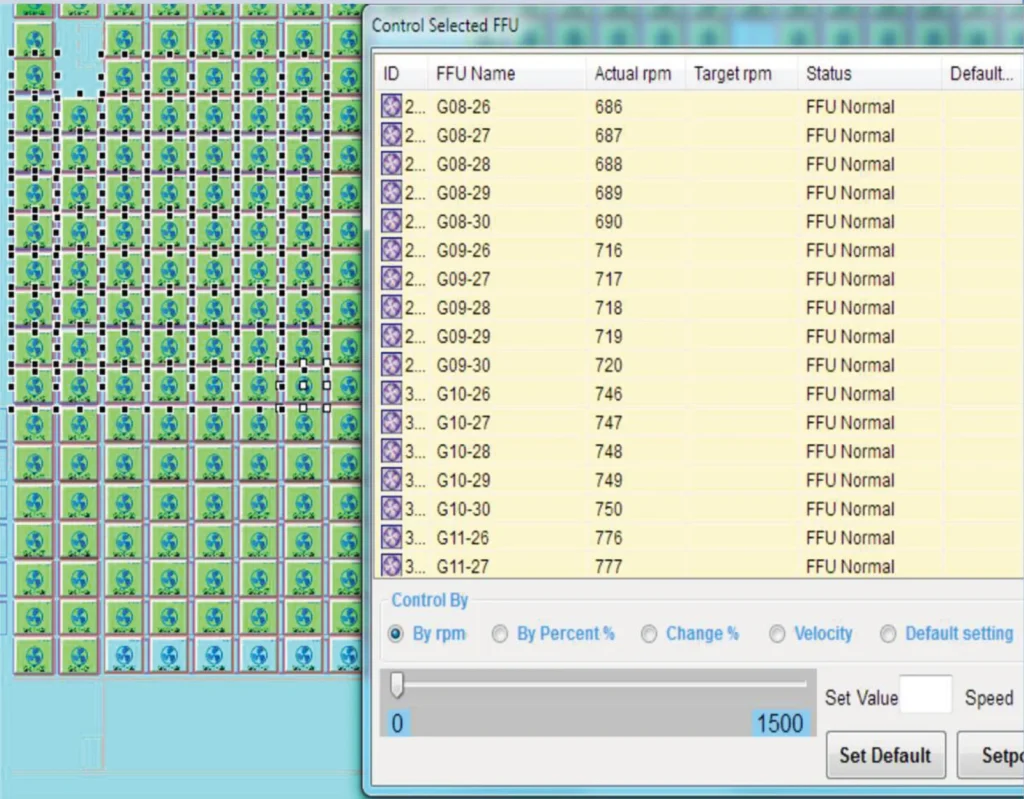

Control Selected FFUs

Press and hold mouse left button, and draw a rectangle to select multiple FFU, double click at selected FFU or right click to shown popup menu, and select <Control Selected FFUs>

• By rpm, Enter new rpm to control selected FFU;

• By Velocity, select control by <Velocity>, and enter set velocity value 0.xx m/s.

Control individual Group

Select a Group from left hand side tree view panel, right click shown popup menu, and select <Control Selected Group: Group XXX>

Control Selected FFUs

Press and hold mouse left button, and draw a rectangle to select multiple FFU, double click at selected FFU or right click to shown popup menu, and select <Control Selected FFUs>

• By rpm, Enter new rpm to control selected FFU;

• By Velocity, select control by <Velocity>, and enter set velocity value 0.xx m/s.

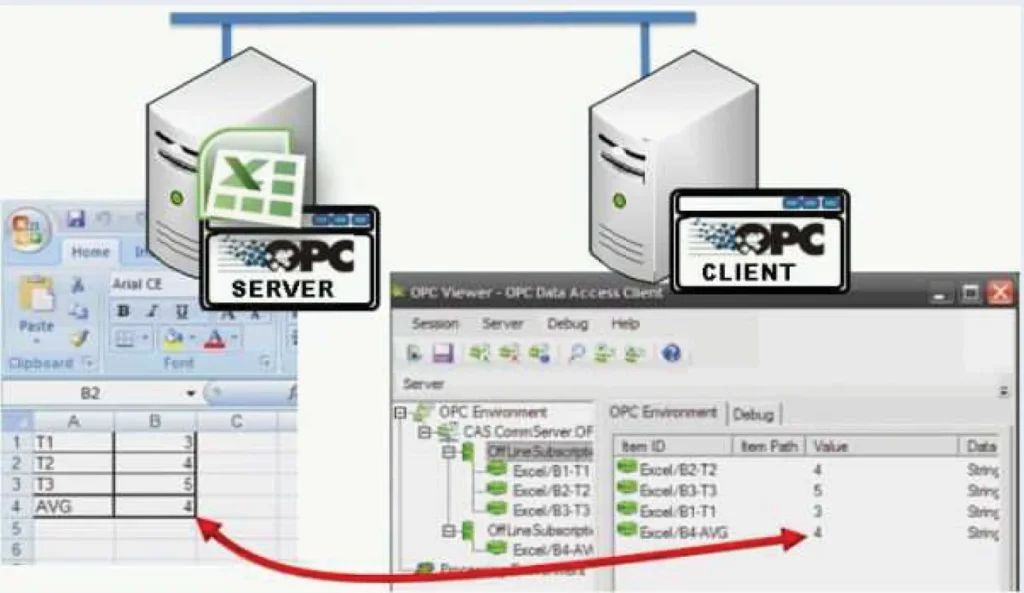

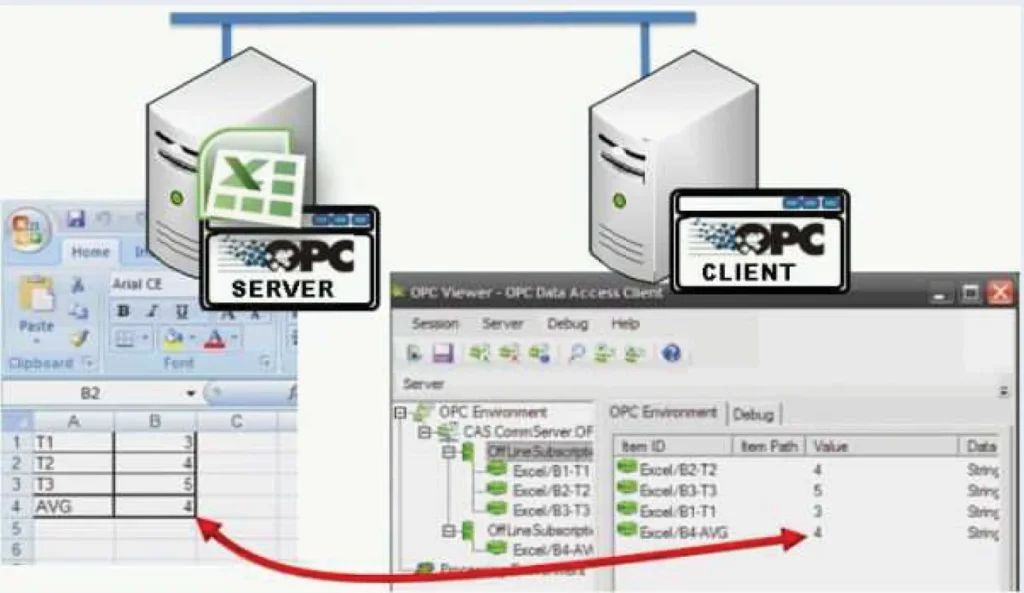

FFU OPC Server

Provide OPC server interface for third party system to read FFU status and Speed

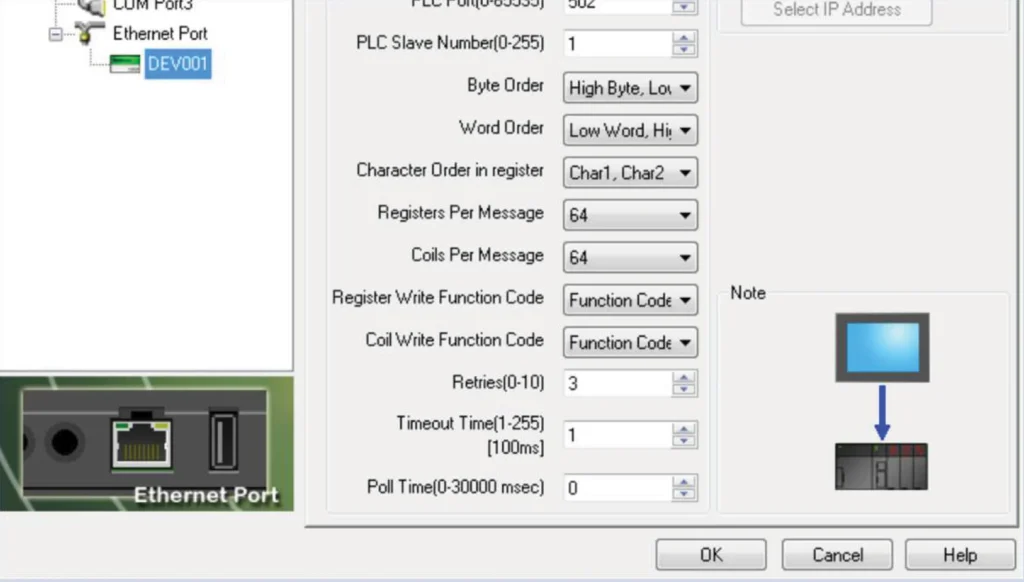

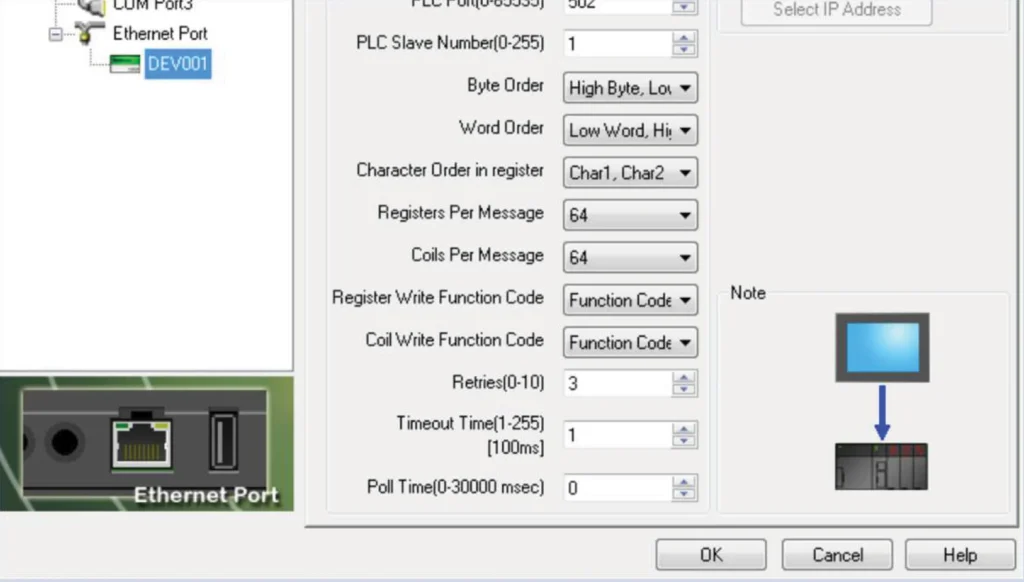

Modbus TCP/IP

Provide Modbus TCP/IP server for third party system to read FFU status and Speed, set FFU speed is optional features.

Third Party

System Integration

FFU OPC Server

Provide OPC server interface for third party system to read FFU status and Speed

Modbus TCP/IP

Provide Modbus TCP/IP server for third party system to read FFU status and Speed, set FFU speed is optional features.

Consult our services

Ready to optimize your clean room environment and ensure compliance with industry standards? Connect with us today for a consultation tailored to your needs!