- No products in the list

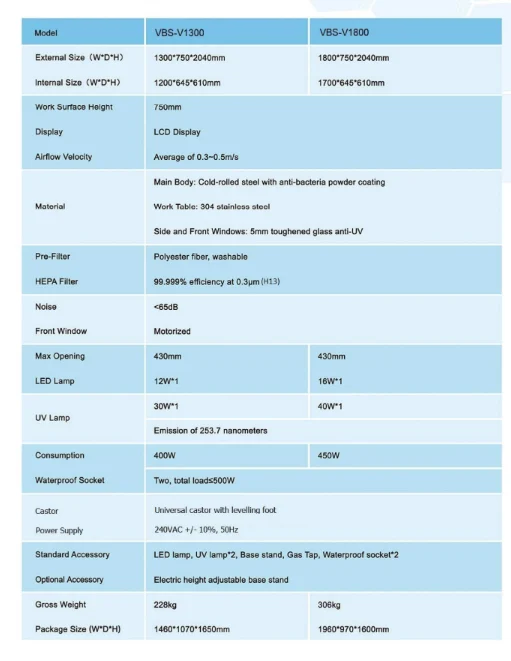

Vertical Laminar Flow Bench

Introducing our Vertical Laminar Flow Bench – the epitome of clean air technology for controlled environments. This specialized bench creates a vertical flow of ultra-clean air, effectively removing contaminants and ensuring a pristine workspace. Ideal for laboratories, cleanrooms, and other critical environments, it provides a sterile working area for sensitive operations. Elevate your facility’s cleanliness standards with our Vertical Laminar Flow Bench, offering reliable performance and peace of mind for your operations.

What is a Laminar Flow Clean Bench and how does it function?

A Laminar Flow Clean Bench is a workstation designed to provide a particle-free working environment by directing filtered air in a unidirectional flow across the workspace. It protects sensitive samples and processes from contamination using HEPA or ULPA filters, making it ideal for labs, electronics assembly, and pharmaceutical settings.

What is the difference between horizontal and vertical laminar flow benches?

In a horizontal laminar flow bench, clean air flows from the back of the unit directly toward the user. In a vertical laminar flow bench, air flows from the top of the unit downward. The choice depends on your workspace setup, the type of work, and safety requirements for your process.

Is a Laminar Flow Clean Bench suitable for handling hazardous substances?

No. A Laminar Flow Clean Bench protects the product, not the user. It is not designed for working with hazardous chemicals, fumes, or infectious materials. For such applications, a biosafety cabinet or fume hood would be more appropriate.

What industries commonly use Vicfil Laminar Flow Clean Benches in Malaysia?

Vicfil’s clean benches are widely used in Malaysian industries such as electronics manufacturing, medical labs, life sciences, precision engineering, and food testing—where contamination control is crucial for product integrity and testing accuracy.

How do I maintain a Laminar Flow Clean Bench for optimal performance?

Regular maintenance includes cleaning interior surfaces with appropriate disinfectants, replacing the HEPA filter as recommended, and conducting airflow and particle testing periodically. Vicfil offers support for filter replacement and performance checks to ensure compliance.

Related products

-

Cleanroom Jumpsuit Storage Cabinet

-

Double-Door Air Shower

Select options This product has multiple variants. The options may be chosen on the product page -

Cleanroom Passbox

-

Vicfil Pressure Relief Damper (VPRD)