- No products in the list

Single-Door Air Shower

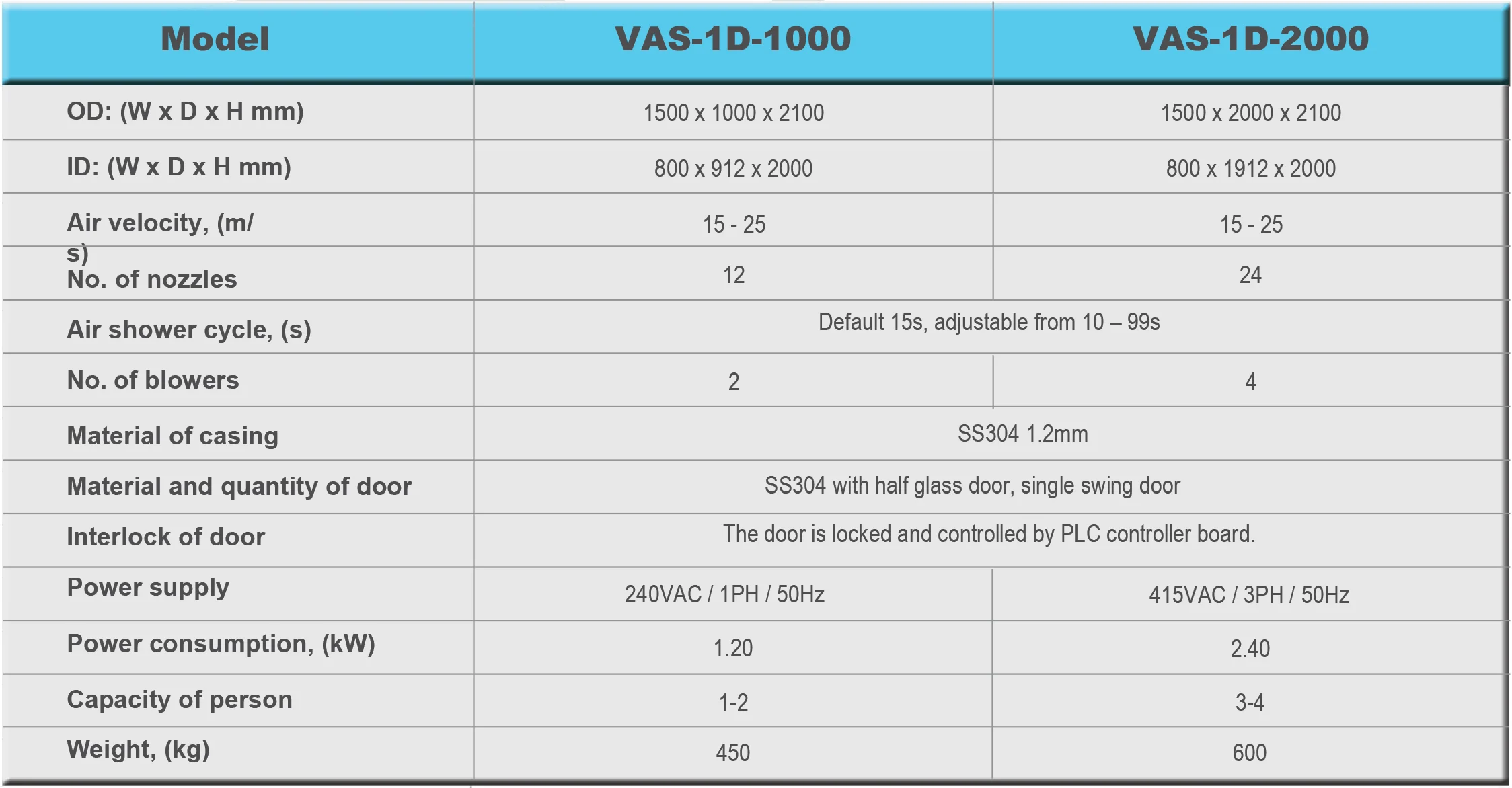

Air shower is specialized enclosed antechambers which are incorporated as entryways of cleanrooms and other controlled environments to reduce particle contamination. Air showers utilize high-pressure, HEPA or ULPA-filtered air to remove dust, fibrous lint and other contaminants from personnel or goods surfaces efficiently. The forceful “cleansing” of surfaces prior to entering clean environments reduces the number of airborne particulates introduced.

When properly incorporated into cleanroom design, air showers provide an ISO-classified transition vestibule to ensure the cleanliness of the classified cleanroom. Air shower is typically placed between a gowning area and cleanroom; after production workers don’t appropriate garb and personal protective equipment, they enter the air shower so that the pressurized filtered air nozzles remove any residual particles from coveralls. Once the program cycle is complete, users exit out through a second door and enter into the cleanroom. Air showers may also be installed between two cleanrooms of different ISO classifications.

What is a clean room air shower?

A cleanroom airshower is a full body clean room and clean air chamber used between to separate two or more rooms with different levels of cleanliness using high-speed, high-volume air jets to remove loose particles and to rapidly dry cleaned surfaces; they are common in electronics manufacturing.

Why use an air shower?

- Key source of contaminants: Workers are a major source for up to 80 percent of airborne particles in clean room shower.

- After high-grade areas: Especially for ISO‑5/Class 100 and higher, such as semicontrol biotech.

- Reduced costs: extends the life of HEPA filters and equipment to avoid product spoilage

What are the different types of air showers?

- Individual stalls (1‑3 people per vehicle)

- High-throughput tunnel-type booths (5 units in total)

- Trolley or material-specific showers with roll-up doors

- Low profile versions for low ceiling cleanroom applications

What materials, used for the construction?

- Common shell materials include stainless steel (high strength and cleanliness), powder or painted aluminium/steel, or plastic laminate, depending upon application requirements like pharmaceutical grade.

What are the key design features?

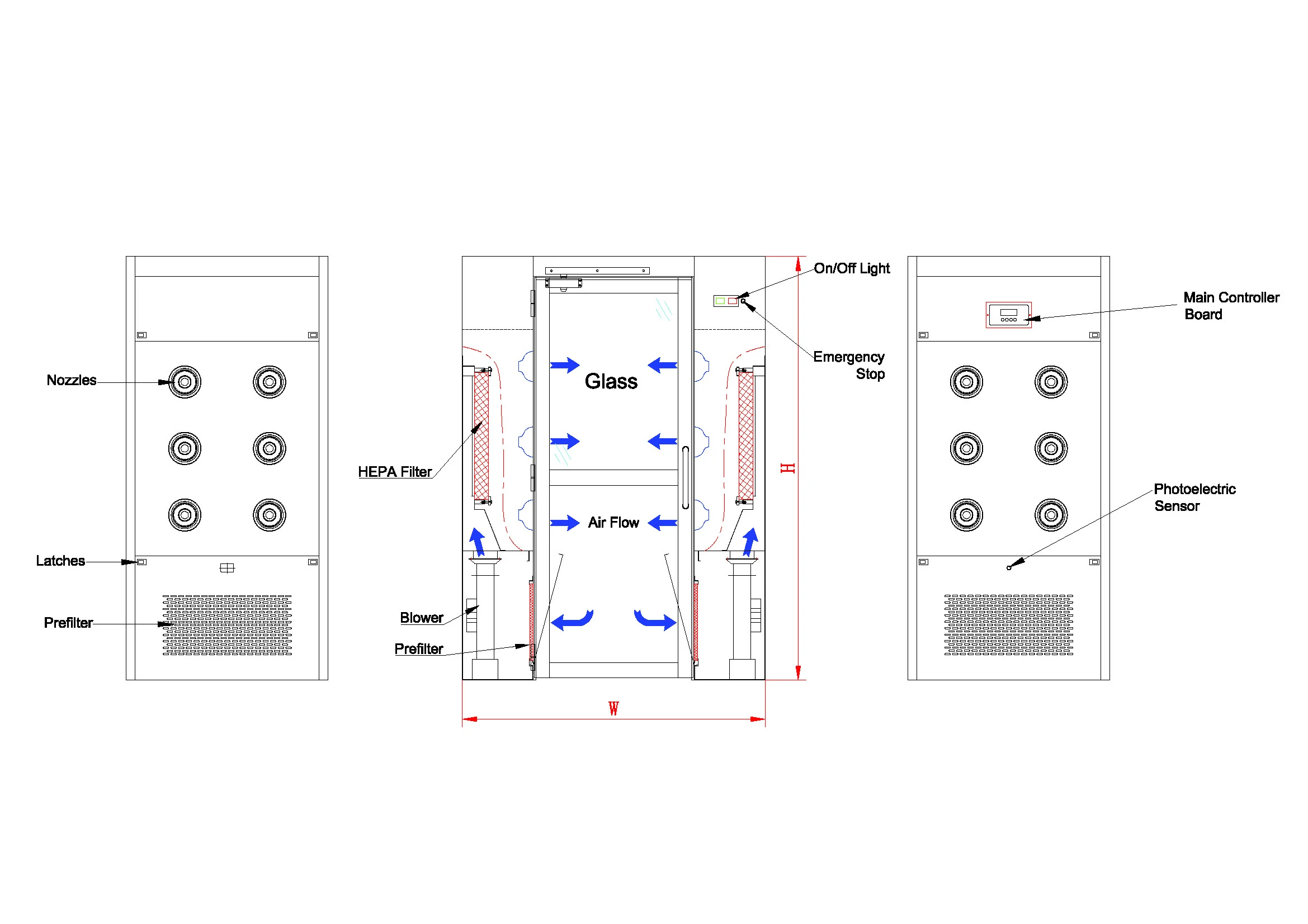

- Interlock doors for maintaining flow

- Flexible and multi-directional nozzles to flap garments and surfaces.

- HEPA/ULPA Filters for Class 100 Airflow Quality

- Cycle start and cycle time are controlled by sensors and timers.

- Optional Ionizers to remove static, positive for electronics cleanrooms.

Related products

-

Double-Door Air Shower

Select options This product has multiple variants. The options may be chosen on the product page -

Fan Filter Unit (FFU)

Select options This product has multiple variants. The options may be chosen on the product page -

70mm Walkable Ceiling Grid

-

50mm Non-Walkable Ceiling Grid